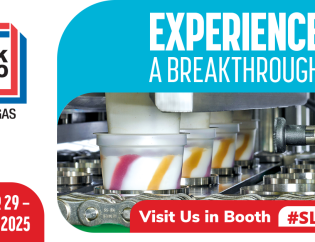

Boost Multi-Product Production with Grunwald Mobile Filling Technology

Food manufacturers and co-packers are under constant pressure to deliver greater variety, handle allergens responsibly, and keep production lines running efficiently. For businesses managing multiple product types, the challenge is clear: how to achieve flexibility and speed without compromising on quality or safety.

Grunwald’s mobile filling and dosing units provide the answer. Compact, versatile, and engineered for precision, these systems are designed to make multi-product production simpler, faster, and more reliable. Unlike traditional fixed machinery, mobile fillers can be repositioned, swapped out, and adapted to suit the requirements of each production run.

What Are Mobile Filling Units?

Mobile filling units are compact, standalone filling and dosing systems designed for flexibility and speed. Unlike large fixed machines, they can be moved into place when needed, operated independently, or integrated into existing lines. For food manufacturers, this means one system can manage a wide range of products, packaging formats, and production volumes—without lengthy changeover times.

These machines are ideal for short runs, seasonal products, research and development batches, or any production environment where flexibility and speed are critical.

Key Benefits for Food Manufacturers

Allergen control is a top priority in food production. Grunwald’s mobile filling units make this simple by allowing the entire filling station to be removed and replaced in minutes. A new unit can be slotted in—already clean, set up, and ready to run. Changeovers take as little as five minutes, eliminating cross-contamination risks and reducing downtime.

Whether filling dry goods like powders, cereals, and snacks, or wet products such as sauces, dairy, and ready meals, Grunwald’s technology handles both with ease. One mobile unit can run a dry fill in the morning and a wet product in the afternoon, giving manufacturers the freedom to manage multiple SKUs without compromise.

Not every product requires high-volume production. For limited runs, trial batches, or seasonal packaging formats, mobile filling units are the perfect fit. They allow manufacturers to operate cost-effectively without tying up larger production lines, giving greater agility to respond to market demands.

With a small footprint and user-friendly controls, these machines can be positioned exactly where they’re needed, stored when not in use, and operated with minimal training.

Precision is vital in maintaining product quality and consumer trust. Grunwald’s engineering ensures drip-free, accurate dosing for every fill, whether the product is free-flowing, pumpable, or more complex.

Solving Key Production Challenges

Grunwald’s mobile filling units are built to address the real challenges faced by modern food manufacturers:

- Allergen management and food safety compliance

- Reducing downtime during changeovers

- Managing diverse product portfolios with one machine

- Meeting seasonal and short-run demands without waste

- Ensuring long-term machine reliability with German-engineered quality

Transform Your Production Process

For food manufacturers and co-packers looking to increase efficiency, manage allergens, and diversify product output, Grunwald’s mobile filling solutions are a proven investment. By combining rapid allergen-free changeovers, precision dosing, and unrivalled flexibility, these machines deliver the adaptability required in today’s fast-moving food industry.

learn more about our mobile filling technology and how it can support your next project.